In batch processes with changing viscosities, the EKATO PARAVISC can also be equipped with inner baffles to achieve sufficient power input even at low viscosities.įor products showing strong structural viscosity, substances with a pronounced yield point or suspensions with a low liquid content, the EKATO PARAVISC can act as a frame impeller within a coaxial mixing system. This is also the region with the highest energy dissipation. The maximum shear induced by this impeller is located in the gap between the vessel wall and the impeller.

This ensures that mixing occurs at all points in the vessel and that no dead zones can develop. From the centre of the surface, it flows to the walls and is then pulled downwards again by the impeller blades. An agitator will give a more random movement to the fluid, while an impeller will produce a directional flow. An impeller is a propeller (fan blades) in an enclosed duct or tube.

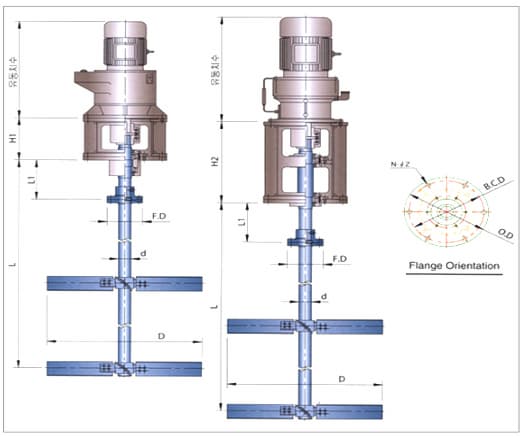

For example, if it is pumping downwards, the fluid is forced downwards along the wall, is deflected by the vessel bottom and then flows back upwards along the agitator shaft to the surface. Answer: An agitator is a generally blunt moving projection that stirs fluid. The EKATO PARAVISC can be operated so that it pumps either downwards or upwards, depending on the application case. It perfectly fits waste water applications, especially primary and secondary flocculation, thanks to the design of our 2PM-0650 Premium 2-blade high-efficiency impeller that grants several advantages and benefits compared to other flocculation systems (e.g. Such impellers are mainly used for fluids with a high viscosity or in media with a critical rheology.Īxial mixing with this impeller is achieved by means of a simple shape and arrangement of both main blades. PRO-DO-MIX ® ACR agitator is specially designed to ensure high flow rate with gentle mixing. These impellers usually operate in the laminar regime, and the contents of the vessel are circulated by means of an axial pumping action. The EKATO PARAVISC belongs to the group of impellers with a small wall clearance.

0 kommentar(er)

0 kommentar(er)